Omeprazole API remains one of the most widely used proton pump inhibitor (PPI) active pharmaceutical ingredients globally. With its strong demand in gastroesophageal reflux disease (GERD), acidity, ulcers, and H. pylori therapy, manufacturers and formulation companies must ensure that their Omeprazole API meets the highest quality standards.

However, identifying a reliable Omeprazole API supplier can be challenging if you are not fully aware of the key quality parameters. Factors like purity, assay, impurities, stability, synthesis process, and price play a crucial role in determining API performance, regulatory compliance, and final product efficacy.

In this detailed guide, we break down the critical quality attributes (CQAs) of Omeprazole API and help procurement teams, importers, and formulation companies make informed decisions.

Understanding Omeprazole API and Its Role in Formulations

Omeprazole is a benzimidazole derivative and a well-established proton pump inhibitor (PPI).

It works by inhibiting gastric acid secretion, making it effective in:

- GERD

- Peptic ulcer disease

- Zollinger–Ellison syndrome

- NSAID-associated ulcer prevention

- H. pylori eradication therapies

Because efficiency and stability are highly sensitive to quality, the pharmaceutical manufacturers who buy Omeprazole API must ensure that every incoming batch meets stringent pharmacopeial and regulatory specifications.

Why API Quality Matters in Omeprazole API

Omeprazole is known to be a chemically sensitive molecule.

It degrades quickly with exposure to:

- Light

- Heat

- Moisture

- Acidic environments

Low-quality Omeprazole can result in:

- Reduced potency

- Higher degradation products

- Lower stability of finished formulations

- Increased failure in dissolution studies

- Regulatory non-compliance

Hence, assessing the right quality parameters becomes non-negotiable for consistent production.

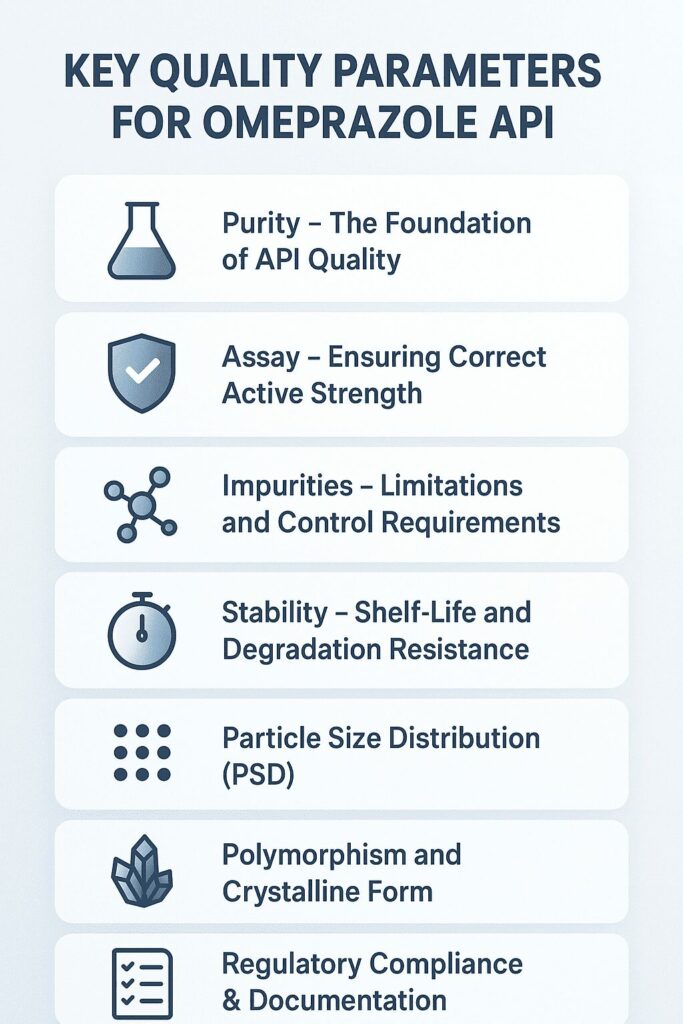

Key Quality Parameters for Omeprazole API

Below are the most important parameters evaluated by formulation manufacturers and regulatory authorities.

1. Purity: The Foundation of API Quality

Purity indicates the percentage of the API that is chemically identical to Omeprazole.

Typical pharmacopeial purity standards require ≥ 99% purity.

Why purity matters:

- Ensures consistent therapeutic effect

- Reduces unexpected side reactions

- Increases formulation stability

- Lowers the risk of impurities accumulating in the product

How purity is measured:

- HPLC analysis

- UV spectroscopy

- Mass spectrometry (for advanced verification)

The purity of Omeprazole API should be free from solvent residues, heavy metals, and organic impurities. A supplier with advanced purification processes (like crystallization, high-efficiency filtration, or controlled synthesis steps) can maintain consistently high purity levels.

2. Assay: Ensuring Correct Active Strength

Assay represents the actual concentration of Omeprazole present in the API. Most pharmacopeias (USP/EP/IP) specify an assay range of:

98.0% – 102.0%

Why assay is critical:

- Ensures dosing accuracy

- Prevents under- or over-formulation

- Maintains batch-to-batch consistency

- Helps meet regulatory and cGMP criteria

Assay testing is generally performed using HPLC to ensure the molecule meets identified structural standards.

3. Impurities: Limitations and Control Requirements

Impurities are unavoidable in any chemical synthesis process but must be controlled within acceptable limits.

Types of impurities in Omeprazole API

- Organic Impurities

- Process-related intermediates

- Degradation products

- Side-reaction by-products

2. Inorganic Impurities

- Reagents

- Catalysts

- Residual metals

3. Residual Solvents

- Mainly from crystallization or extraction phases

Why is impurity profiling essential?

- Impurities directly impact safety and efficacy

- Regulatory agencies require detailed impurity monitoring

- Some impurities may be toxic or unstable

- Impurities affect color, odor, and stability of the final drug

Typical impurity limits

- Single impurity: ≤ 0.1%

- Total impurities: ≤ 0.5%

- Residual solvents: As per ICH-Q3 guidelines

A reliable Omeprazole API supplier conducts advanced impurity profiling using:

- HPLC

- LC-MS

- GC-MS

- ICP-MS (for metal traces)

Proper impurity control ensures better formulation stability and longer shelf life.

4. Stability: Shelf-Life and Degradation Resistance

Omeprazole is extremely light-sensitive and heat-sensitive.

Highly unstable under:

- UV exposure

- High temperature

- Moisture

- Acidic conditions

Good quality Omeprazole API must include:

- Verified stability studies (ICH Q1A)

- Forced degradation data

- Real-time and accelerated stability profiles

Stability directly affects:

- Packaging choices

- Storage conditions

- Transportation standards

A stable API ensures predictable performance in finished dosage forms like tablets, pellets, capsules, and sachets.

5. Particle Size Distribution (PSD)

This parameter is often overlooked but is vital for formulation performance.

Why PSD matters:

- Affects dissolution rate

- Influences absorption

- Determines pellet coating uniformity

- Impacts flowability in manufacturing

Formulators typically require controlled micron ranges, depending on dosage design.

6. Polymorphism and Crystalline Form

Omeprazole may exist in different crystalline forms.

A consistent polymorph ensures:

- Uniform bioavailability

- Predictable stability

- Smooth pellet extrusion and spheronization

A reputable API supplier provides polymorphism analysis and documentation.

7. Regulatory Compliance & Documentation

A high-quality Omeprazole API supplier should provide:

- DMF / CEP availability

- COA for each batch

- MSDS

- Stability data

- Impurity profile

- Residual solvent analysis

- Manufacturing under WHO-GMP / cGMP

Quality compliance builds trust and ensures trouble-free regulatory submissions for finished formulations.

Omeprazole API Price: What Determines the Cost?

Price is a major factor when sourcing Omeprazole API, but cheapest is not always the best, especially with sensitive molecules.

Key factors affecting Omeprazole API price

1. Purity and Assay Levels

Higher purity and perfect assay control require:

- Better raw materials

- Advanced purification processes

- High-precision analytical systems

This raises production cost.

2. Impurity Control

Tight impurity limits mean:

- Additional synthesis steps

- Higher validation requirements

- More stringent testing

3. DMF/CEP Availability

- Regulatory filings increase API credibility and cost.

4. Production Scale & Technology

Large-scale, automated GMP plants offer consistent quality but at higher investment.

5. Market Dynamics

Raw material prices, global demand, and supply-chain issues impact pricing trends.

6. Contract Terms

Price varies based on:

- Order volume

- Annual contracts

- Shipment frequency

- MOQ

Balancing cost and quality

Formulators should aim for cost-effective Omeprazole API without compromising on:

- Stability

- Impurity limits

- Batch consistency

- Regulatory compliance

Going only for the lowest price often results in higher rejection rates and increased production costs later.

Tips for Choosing a Reliable Omeprazole API Supplier

To ensure consistent quality, look for suppliers who provide:

- Consistent assay and purity results

- Low impurity profile (well below pharmacopeial limits)

- WHO-GMP / USFDA-compliant manufacturing

- DMF/CEP support

- Dedicated QC and QA teams

- Transparent COA with every shipment

- Strong global export experience

When sourcing Omeprazole API, partnering with suppliers who prioritize quality and regulatory compliance is essential. Thykn (India) International has built its presence in international markets by supplying APIs that adhere to strict impurity limits, stable assay values, and reliable batch consistency. With a focus on transparent documentation and dependable service, Thykn supports formulation companies and importers in maintaining high manufacturing standards and avoiding production delays or regulatory challenges.

Final Thoughts

Choosing the right Omeprazole API supplier requires evaluating purity, assay, impurities, stability, and consistency. Because Omeprazole is a sensitive molecule, even minor deviations can affect formulation performance and shelf life.

By working with trusted, quality-focused suppliers, pharmaceutical manufacturers can ensure predictable results and smoother regulatory pathways. Thykn aims to support buyers with dependable Omeprazole API quality, clear COAs, and a strong commitment to meeting global standards, helping partners maintain reliability in every batch they produce.

High-quality Omeprazole API does more than ensure drug effectiveness; it strengthens your brand reputation and builds long-term trust in the pharmaceutical supply chain.